3.2Meter SSS Spunbonded Nonwoven Machine

I、Usage

(1)Medical and health usage:operation suit、garment、face mask、diaper、sanitary napkin、disposable hygiene product. etc;

(2)Home decoration:shopping bag、wall covering fabric、table cloth、bed sheet、bedspread. etc;

(3)Lining for clothes or shoes:lining、adhesive interlining、shoe lining. etc;

(4)Agricultural usage:Protection cover、nursery cover. etc;

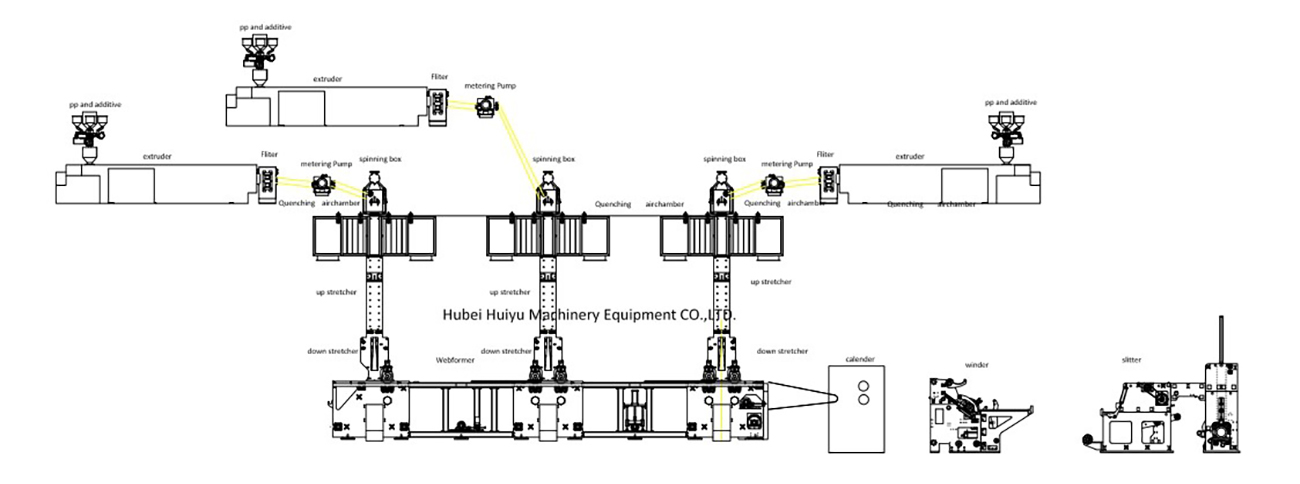

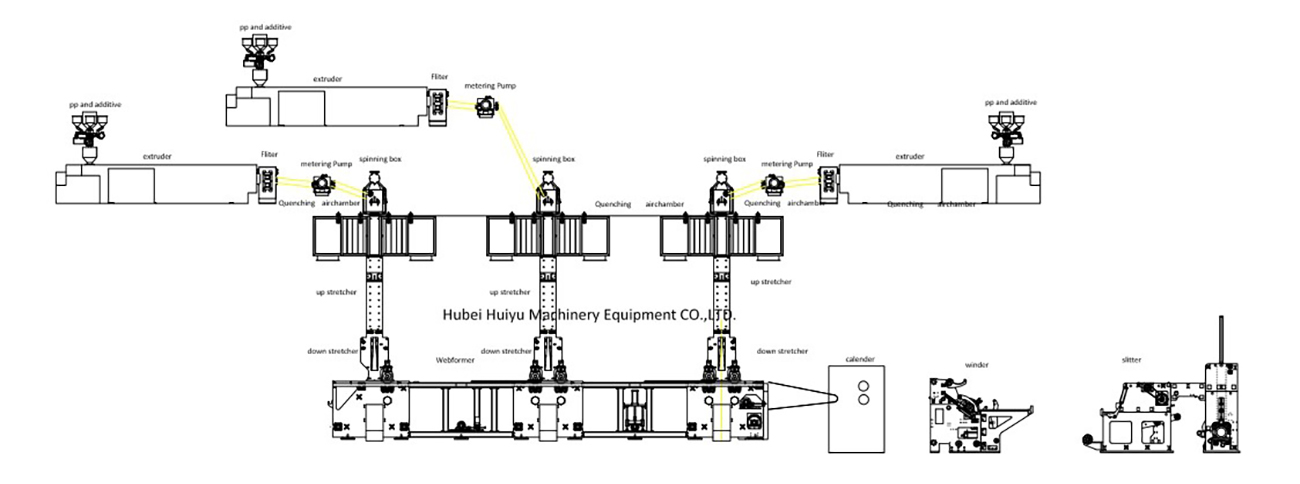

II、Sketch

The first S spunbonded nonwoven machine in China invented by Huiyu has the following features:

With equipments from famous manufacturers in China and abroad, combined with mature technology from Huiyu, Our S nonwoven machine is quite advanced, stable and reliable

Huiyu S machine choose the key equipments from the following companies :

Zhoushan Jinhu---------------------Screw extruder

Qiaode-------------------------------Calender

ABB ------------------------------ frequency converter

Siemens------------------------------PLC

Low voltage components-----------CHNT

With equipments from famous manufacturers in China and abroad, combined with mature technology from Huiyu, the technology、development、producing and the feature of machines are all very advanced among the similar equipments ,so can ensure the high quality for the production line.

Huiyu is a professional manufacturer for the spunbond melt technology production line. Successful research S、SS、SSS、SMS、SMMS、SSMMS production line ,with the best technology and strong project capacity.

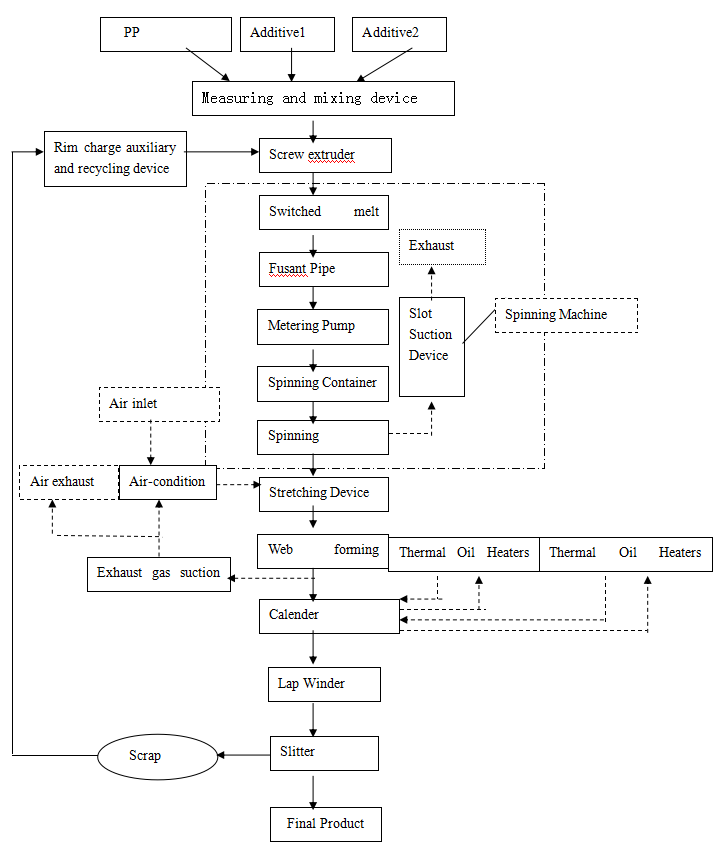

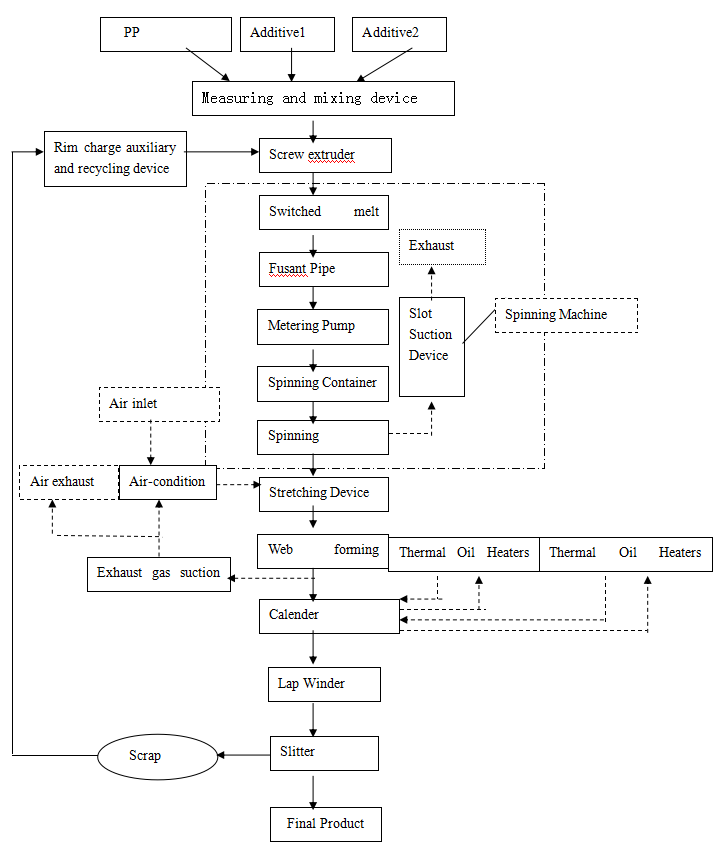

III、Technical Process

IV、Main technique parameter:

1.PP chips requirements

1.1MFI: 35-45g/10min±1% per block

1.2 Melt point:166℃

1.3 Ash: <0.15-0.25%

1.4 PP color master batch and additives

2.Products Width:3200mm

3.Filament denier:1.8-2.3denier

4.Output:about 9000Ton

5.Weight range:12-70g/m2

6.Maximum diameter of fabric per roll:1200mm

7.Design speed:≦350m/min

8.Running speed:≦350 m/min

V、Labor arrangement

15 workers three shift per day,

Carry workers:3 persons

Salesman:3-5 person.

Technical engineer:2 person

VI、Workplace:

Size of machine: W*L*H=30m*17m*10.5m

Suggested workplace area: 50m*25m(including material and final product warehouse)

Height of workplace:Fore-spinning 12m,Back spinning 5.5m

VII、Public Project

Install capacity of the whole production line: about 1600KW, actual power:900KW, main

voltage:3*380V,50Hz; Cycling water:80m3/H(25°С,0.2-0.35mpa),water supply ability:5-10m3/H

VIII、Approval standard for equipments

|

Items

|

g/m2

Specification

|

15

|

30

|

45

|

|

Allowable deviation(%)

|

First class

|

±8

|

|

Final product

|

±10

|

|

Width deviation(%)

|

First class

|

+2.0,-1.0

|

|

Final product

|

+2.5,-1.5

|

|

Fracture Strength

|

Longitudinal Strength

N≥

|

First class

|

15

|

35

|

50

|

|

Final product

|

12

|

30

|

45

|

|

transverse strength N≥

|

First class

|

10

|

28

|

44

|

|

Final product

|

8

|

25

|

38

|

IX、Machinery quality index, parameter and technical specification

☆Measuring and mixing device

1、Usage

The main usage of this device is to mix PP, and additives as color master batch, antioxidant ,fire retardant with certain ratio

2、Main technical parameter

2.1 Maximum feeding ability: 600㎏/h

2.2 Surge bin capacity:3* 1.5m3

2.3 Maximum additive hopper:3

3、Facilities and specification

3.1 Surge bin 3 set

Effective capacity:1.5 m3.Main material: stainless steel. Set up a low level alarm device.

3.2 Measuring and mixing device 3 set

It is made up of 1 main hopper ,2 accessory hoppers ,vacuum feeder , metal detector and so on. Set up high level and low level alarm device, auto control feeding device .Electrical motor of screw in mixing device is frequency converting.

☆Rim charge auxiliary screw and recycling unit

Usage: recycle the rim

Recycling screw use the alternating frequency converter

Screw diameter: φ105

Screw heating zone number:4 zones

☆135type screw extruder

1、Usage

The main usage of this device is to squeeze and melt PP, and additives as color master batch, antioxidant, fire retardant .

2、Main technical parameter

Screw diameter: Φ160*3,Max extrusion output: 520㎏/h

Screw rolling speed: 60r/min

Screw heating zone number:7 zones

AC motor

Facilities and specification

The device contains feed inlet, auto heating and cooling system and overpressure alarm system.

☆Screw spinning machine

Usage

The PP melt go through filter, melt pipe, and metering pump transport the fusant into spinning container and fiber comes out from spinneret.

Main technical parameter

2.1 Output: about 9000t/year

Fiber denier: 1.8-2.3denier

Weight range: 12-70g/㎡

2.2 Switched melt filter

Filter ratings:250 section

Diameter:172mm

2.3 Metering pump and transmission unit

Pump offering quantity:300CC*3

Frequency converter control synchronous machine, made in ShanXi

2.4 Spinning container

Heating pattern: Oil heating

2.5 Melt pipe

Heating pattern: Oil heating

2.6 Monomer suction device

Air pressure:1300Pa

Flux: 844m3/h

2.7 Spinning component

Hole diameter:0.42mm

L/D:1:5

Material:SUS431

☆Stretching device

Usage: stretching and cooling the fiber.

Main technical parameter:

Working width:3200mm Device components

The device contains quenching chamber, up stretching channel, down stretching channel ,diffuse winder tunnel etc. Using double-side symmetry wind to cool fiber,

Stretching slit in down stretching device can adjust according to craft requirements. Adjust system takes torque motor drive.

☆Web forming machine

Usage

Offer carrier for fiber after stretching.

Main technical parameter

Air suction quantity: 42000m3/h

Design speed:350m/min

Normal running speed: ≦350 m/min

Web-laying apron: venting quality: 7,000~10,000m3/h.m2

3. Device components

3.1 web-laying apron transmission device

3.2 Air suction channel

3.3 Sealing device

3.4 Position correcting set

3.5 Tension device

3.6 Rack device

3.7 Pre-roller

☆Calender

Main parameter

Speed:10- 350m/min

Working width:3200mm

Diameter: Φ120mm

Max winding Diameter:1200mm

Roller type: Up roller is embossing roller, down roller is mirror roller.

☆Lap winder

Main parameter

Speed: 10-500m/min

Working width:3200mm

Paper tube diameter: 150mm

Maximum winding diameter:1500mm

☆Slitter

Main parameter

Speed: 10-500m/min

Working width:3200mm

Minimum dividing width:120mm

Maximum fabric diameter: Φ1200mm

☆Electrical Control System

Controlled by Siemens PLC and ABB frequency converter. Low voltage components: CHNT.

Hubei Huiyu Machinery CO.,LTD.